Press Glass is a leading glass processing company for the construction industry with over 30 years of experience. We process glass for fabricators of windows & doors, facades and interior glass constructions.

Our 15 modern production plants are located in Europe and the USA with 2 new developments underway in the UK and the USA. Screen printing on flat glass

Press Glass’ unique business model has positioned us as a leader in continental Europe, the UK, with an increasingly significant presence in the USA.

We are acknowledged, globally recognized supplier of glass for façades of monumental projects across the world.

From the day of our foundation we develop a unique business model based on individual customer service, building a technological superiority to deliver high quality, energy efficient products for modern, sustainable buildings. Driven by a culture of transparency, agility and effective decision-making, we are a strongly customer-focused, cultivating a strong, mutually beneficial long-term relationships.

We are creating a technological advantage in the glass processing industry via the best available technologies developed by our R&D in cooperation with our suppliers. Each of our new factories is enhanced based on our continuous innovations and experience with existing ones. Our new factories are highly automated, energy-efficient and consume less resources to manufacture 1 square meter of the façade glass. Parallelly we optimize operating ones e.g. in the UK, where we are transforming few small factories in one modern super-efficient factory.

We are independent company with the strong cooperative potential - we offer wide portfolio of products from all key flat glass manufacturers across the world to fulfill expectations of clients in different climate zones.

Press Glass develops scalable business with the factories located close to the Clients hubs. Local productions helps also to reduce carbon foot print related to transport and reduces supply chains complexity.

We believe our employees are our greatest asset. We are creating valuable job positions - constant development of the manufacturing base, sales markets and growth competence gives us the opportunity to be better partner for your projects.

Due to our unique business model we are highly cost effective and competitive in the glass processing industry. Based on our innovations and operational superiority we are strongly profitable business with EBITDA continuously over 10%.

Our mission is to be an active partner in the global transformation of the construction industry towards energy efficient, green buildings.

Press Glass discovered an unprecedented opportunities of glass as a key sustainable building material of the future. Our advanced, energy efficient products help to reduce energy consumption of modern buildings, while increasing the comfort of its inhabitants, due to improved daylight conditions.

Our world-class equipment combined with renewable energy sources contributes to the sustainable industry and green cities.

Thermal protection is the basic task of glazing units designed for windows. Thanks to our partnership with suppliers, resulting in development of new glass coats, PRESS GLASS is able to offer glass panes with even lower heat transfer coefficient Ug= 0,4 W/m2K. This value is close to the value of heat transfer coefficient of walls. Cold feet near the window are in the past. All the people who want to save on heating in winter thanks to solar heat gains from the sunlight coming through window panes and are not concerned with overheating in summer, can now purchase heat insulating window panes with increased coefficient g=73%.

In summer the sun emits much large quantities of thermal energy, as compared with winter. Overheating is observed, mostly due to heat transfer through window panes. The grade of summer overheating protection is expressed in coefficient g. Its lower value defines better efficacy of the protection against overheating. Our offer of heat-insulating glass panes includes also such structures that reduce the overheating effect with coefficient g=37%. Today the technology so far reserved for facades can be also be used in all houses. Now everybody can improve their thermal comfort while reducing the operating costs of mechanical air conditioning system installed. It is worth to remember that costs of cooling the premises are higher than costs of heating.

The level and distribution of air temperatures has a significant impact on our comfort while indoors. Until recently it was possible to feel a dramatic drop in temperature near a window during the winter, which could produce a strong feeling of discomfort. Thanks to the application of thermally insulated glass which amounts to 70% of the window surface it is possible to eliminate this problem the range of temperatures are not subjected to any heat discomfort. A different problem can arise in the summer, when the sunrays overheat the inside of a building. This problem can be rectified by reflexive solar control and selective solar control glass which, thanks to its special construction, limits overheating while maintaining a high level of light transmission. A similar function is also provided by thermal control glass, but to a lesser degree; this is compensated by the benefit of higher heat retention performance during winter that thermal control glass offers.

HIGH LEVEL OF LIGHT TRANSMISSION

One of the particularly important qualitative characteristics of glass is light transmission. This has a particular influence on the well-being of people who use the room in question. As research shows, poor light transmission into a room can be the cause of a bad frame of mind. PRESS GLASS pays particular attention to this characteristic when preparing a market offer.

REDUCING THE COSTS OF HEATING

Everyone who receives the heating bill wonders about ways to reduce such expenses. At present economizing on heat energy is the main task which faces producers of double-glazed units. PRESS GLASS perfectly understands these needs and offers a few solutions thanks to which it is possible to significantly reduce the costs incurred when heating a building.

It offers quality and beauty, helps save energy, and allows for easy assembly. Among its various qualities, there is one which is especially useful for offices and public facilities, namely solar protection. Solar control glass adds character to a building and reduces undesirable heating of the elevation regarding a type of coating.

Solar control glass can be divided into absorptive and reflective glass, based on their visual characteristics and the ability to reduce solar radiation.

The level and distribution of air temperatures has a significant impact on our comfort while indoors. Until recently it was possible to feel a dramatic drop in temperature near a window during the winter, which could produce a strong feeling of discomfort. Thanks to the application of thermally insulated glass unit which amounts to 70% of the window surface it is possible to eliminate this problem the range of temperatures are not subjected to any heat discomfort.

A different problem can arise in the summer, when the sunrays overheat the inside of a building. This problem can be rectified by reflexive solar control and selective solar control glass which, thanks to its special construction, limits overheating while maintaining a high level of light transmission. A similar function is also provided by thermal control glass, but to a lesser degree; this is compensated by the benefit of higher heat retention performance during winter that thermal control glass offers.

REDUCING THE COSTS OF VENTILATION

As in the winter period when there is a necessity to heat a building, likewise in the summer period there is heating of parts of the building on the southern, south-eastern and south-western parts. Sunshine which is evident during the day emits a lot of heat energy, which during winter is seen as additional heat which heats up a building, while in summer it causes excessive rises in temperature causing discomfort and worsening of work conditions. In order to reduce temperature in homes or office buildings air-conditioning systems are commonly used. This is associated with additional costs and it is worth noting that the costs of cooling buildings is higher than the costs of heating.

So as to reduce the costs of cooling it is necessary to apply the following types of glass in windows and facades of buildings:

– Solar control glass units which are dyed in mass – Reflexive solar control glass units

The application of such glass, especially that which is dyed in mass during the winter period can cause reduced light transmission to a building especially on the northern side.

In order to preserve the high level of light transmission, as well as significantly reducing the infiltration of solar energy it is necessary to use the following:

– Selective solar control glass (dual function)

See gallery of Solar Control Glass 360 degrees - https://www.pressglass.com/market-offer/glazed-units/solar-control-glass-2/gallery-of-solar-control-glass-360/

The application of plastic or stainless steel warm spacer bars reduces Psi coefficient to 35% in relation to panes with aluminium spacer bar. The effect of this is an increase of window temperature from the side of the room on the contact of frame with glass unit. With the effect that permissible relative air moisture, which in given conditions forms water vapour may due to the application of “warm edges” be higher by approx. 10-15% and shall not cause occurrence of water vapour condensation.

The permissible external minimal temperature is also reduced, at which water vapour condenses on pane surfaces.

Method of calculating coefficient of heat penetration of window Uw, in which the influence of the connection of the frame with the pane is taken into account is indicated in Standard EN ISO 10077 in the form of the following formula:

REDUCTION OF THE LINEAR HEAT LEAKAGE BRIDGE ON THE EDGES OF THE GLASS UNIT

The properties of thermally insulated glass are also influenced by the linear heat conductivity on the edges. Up to now aluminium spacerbars have been commonly used, which are essential elements of glass units, but they have proved to be poor elements in making double glazed glass units. Aluminium is a much better carrier of heat than the remaining parts of the window construction, so the aluminium spacerbar is the final exit point for heat to move from the interior to the external area. The solution to this problem is to apply a spacerbar known as “ a warm edge”, which is made from highly insulating material or precious steel.

LIMITATION OF CONDENSATION OF THE EDGES OF THE GLASS UNIT

The solution to this problem is to apply the spacerbar known as “the warm edge”, which is made of highly insulating material or precious steel. The application of the warm edge improves the thermal insulation along the edges, which in turn increases the temperature in this area and reduces the risk of temporary water vapour condensation.

ENSURING LONG-TERM CORRECT TIGHTNESS OF GLASS UNITS

MAXIMASING SAVINGS OF HEAT ENERGY LOSSES THROUGH REDUCTION OF THERMAL BRIDGE CONNECTING FRAME WITH PANE

See GALLERY OF WARM EDGES COLOURS:

https://www.pressglass.com/market-offer/glazed-units/glazed-units-with-warm-edge/gallery-of-warm-edges-colours/

Safety glass minimizes the likelihood of accidents resulting from impact or fractures. Security glass is engineered to withstand deliberate attacks, including manual or ballistic.

Security glass is used in cases when we want to protect a given building, while also preserving the aesthetic of the elevation or partition walls by eliminating window bars, shutters or roller blinds.

Safety glass protects against injury at breakage, making it less possible to break the glass when lamming a door or window.

TEMPORARY PROTECTION AGAINST BREAK-IN ATTEMPTS

It would appear that glass in windows are the weakest element of a house with regard to prevention of burglaries. Modern solutions however, allow for the successful temporary prevention of burglary. This is realized by the application of laminated glass composed of 2 glass panes and several layers of PVB foil between the panes depending on the level of danger. All glass units on offer fulfil the requirements of EN 356 standard.

PROTECTION AGAINST INJURY FROM BREAKING GLASS

The threat of injury during glass breakage exists in any place where the users of a building are in direct contact with glass partitions, especially in areas of communication. In order to prevent such danger Press Glass proposes 2 types of solutions:

All glass units on offer fulfil the norms of EN 12600 specifications.

REDUCTION OF RISK REGARDING CRACKS

If, due to the conditions of use, there is a threat of breakage in the glass units it is necessary to use laminated glass. Thanks to the properties of laminated glass, the glass panes stay safely in the window frame or bolted elements even after a blow or smashing.

Protection against noise is one of the most important issues in our lives. The condition of assuring appropriate comfort and sometimes living in a given place is the assurance of a low level of noise.

Our subjective perception of noise is subject to the following principle: if the level of noise in a room is reduced by 10 decibels with relation to that outside, we get the impression that it is reduced by half. Noise protection must be applied everywhere where noise cannot be completely eliminated. In such applications we are faced with acoustic double glazed units.

Acoustic double glazed units are constructed basing on the asymmetry of the assembled panes of glass, flexible bonding of the panes, and the use of attenuation gases in the space between the panes. Acoustic double glazed units can achieve the acoustic insulation factor Rw = 30 – 53 dB, depending on the type of unit. Before choosing a suitable unit, the source of noise should always be specified and other influential factors should be identified.

Check our acoustic glass and choose the best one using filters: https://tools.pressglass.com/soundproof-glass-configurator/table-grid/#/en/global

You can also check our soundproof glass configurator available on this site: https://tools.pressglass.com/soundproof-glass-configurator/en

Why don't you check live how our acoustic glazed units work? Use our inuitive-to-use simulator and find out about noise reduction on your own.

http://nds.pressglass.com/?lang=en

The continuing tendency to use glass in internal and external applications ensures the pleasant appearance of buildings and removes the barrier between the building and the outside world. However, the glazed separators must in many cases meet the fire-fighting regulations relating to flame-retardation and the safe evacuation of the building users. Those requirements are very often met through the use of fire-resistant glass.

PRESS GLASS offers PYROBELITE & PYROBEL fire-resistant glass manufactured by the AGC. It is multi-layered glass, where the sheets of float glass are connected by means of intermediate layers made of gel, which expands under high temperature. During a fire, when the temperature rises to 120°C, the gel layers expand forming a hard, non-transparent layer, which temporarily prevents fire propagation.

Our products meet two basic criteria specified in building standards:

PRESS GLASS marks fire resistant glass units known as Pyrobel and Pyrobelite with a permanent stamp which includes the following:

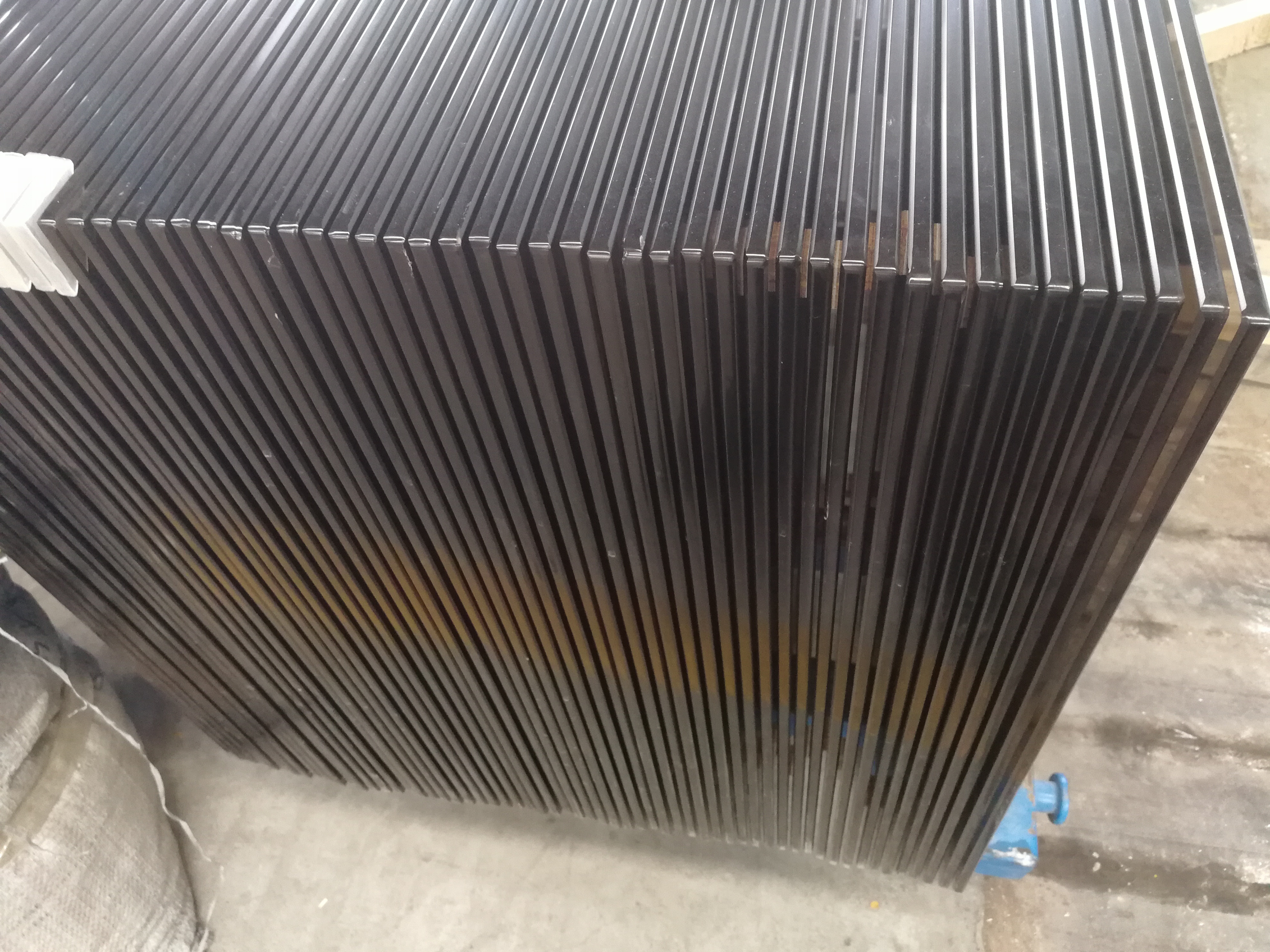

PRESS GLASS Company produces glass with silk-screen printing according to the standard palette of colours and patterns. When making an order, one should give the pattern number of silk-screen as well as the colour from the standard palette. Realization of individual orders requires consultation and the establishment of conditions with a representative of PRESS GLASS.

With regard to the fact that drying and hardening of the silk screen on the glass surface take place during tempering, the glass must be machined beforehand e.g. cutting, drilling of holes, grinding and polishing. In the case of interest regarding a wider palette of colours please contact the representatives of PRESS GLASS.

Digital print on glass by DIGITAL PRINT brings the colourful world of photographs and computer graphics – previously available only in paper and film print – directly to building constructions. Now, thanks to ceramic paints, heated during the toughening process, a graphic can become a weatherproof and vandal resistant part of a glass structure.

Due to using the same print method as used in computer printers, DIGITAL PRINT is extremely fast and does not require any additional work except for processing the graphic file. As it is not necessary to prepare printing screens, even unique patterns remain cost-effective. Use of six basic colours guarantees a photo-quality print at 360 dpi resolution. Thanks to software which allows dividing the overprint graphic into adjacent glass panes, large format photographs covering a glass façade surface can be obtained.

PRESS GLASS offers single glazed units and glazed units, cylindrically bent glass panes based on monolithic float glass, non-coated or with thermal insulating and solar control coatings, tinted or laminated glass.

Screen Printing Glass door To make a product more attractive and to extend the range of its application, bent glass can be covered with screen print or digital print according to standard patterns or individual designs.